Assembrix

Menu

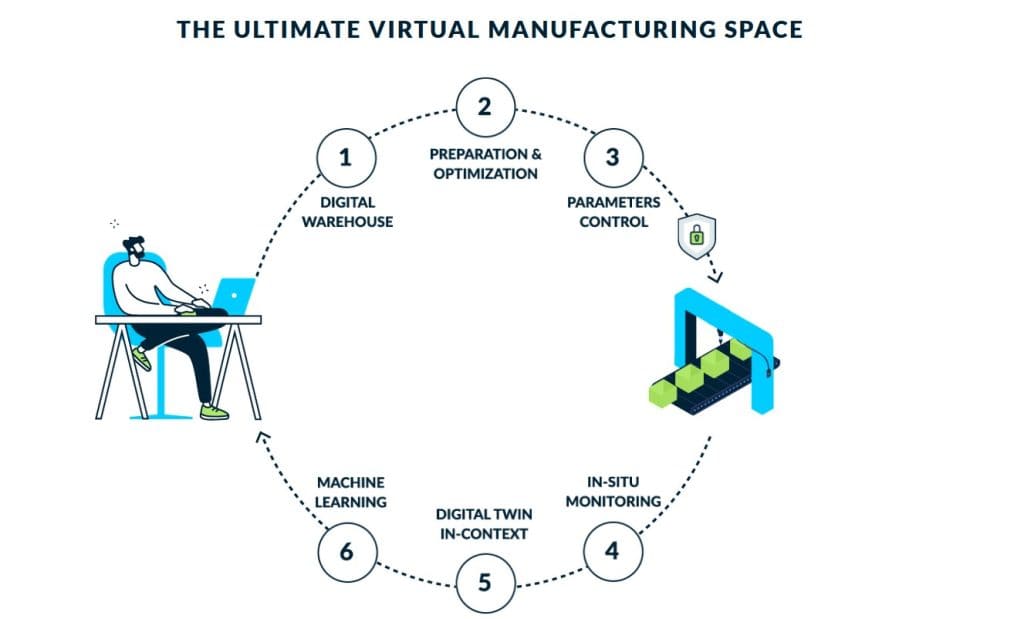

Assembrix VMS allows manufactures to remotely manage the entire Additive Manufacturing digital thread in a fully automated and self-controlled process.

Optimization of the 3D printers supply chain, whether distributed or aggregated, keeps resources and costs to a minimum.

Assembrix VMS applies highest security standards to enable remote manufacturing while maintaining complete ownership and control of the IP throughout the entire automated printing process. A real-time data feed keeps customers updated on the printing status, while advanced blockchain-based encryption ensures IP protection.

For Manufacturers

YOUR DIRECT CONNECTION TO TOP TECHNOLOGIES & QUALIFIED MACHINES

Assembrix VMS (Virtual Manufacturing Space) offers manufacturers and OEMs a direct link to suppliers and service bureaus across the globe, creating instant access to a diverse network of qualified machines employing the latest printing technologies.

Equipped with print preparation and optimization tools to help reduce production costs and lead times.

The cloud-based platform also includes in-situ monitoring, providing manufacturers real-time access to data of the entire process for quality and cost control purposes.

Digital twin-in-context is applied to store and analyze data points and relationships between different parts in the same print batch. In addition, Machine Learning algorithms are applied throughout the process, providing recommendations for better quality control and future cost reduction.

For Suppliers

UNPRECEDENTED INSIGHTS & ACCESS TO CLIENTS ACROSS THE WORLD

Assembrix VMS enables you to allocate manufacturing spaces of industrial 3D printers to multiple clients in real-time based on the specific geometry of the parts – leading to higher printer utilization and ROI.

DIRECT ACCESS TO MANUFACTURERS & CUSTOMERS WORLDWIDE

The robust Assembrix network comprises hundreds of manufacturers across the world from multiple industries, increasing potential revenues by a margin.

DATA & INSIGHTS FOR OPTIMAL CALIBRATION AND PREDICTIVE MAINTENANCE

Assembrix VMS comes equipped with a suite of powerful Maintenance tools to better manage and monitor machines performance, enhance calibrations, alert of required professional services and more.

BETTER CAPEX USAGE OF QUALIFIED MACHINES

Assembrix VMS enables taking full advantage of access capacity. Unused machines and time slots are offered to potential global and local clients, helping to significantly optimize CAPEX usage.

For Partners

Assembrix partners with manufacturers of 3D printers and industrial machines to deliver a more secured end-to-end solution for distributed manufacturing operations.

We are committed to help our partners design more secured software solutions that can be integrated at the machine level (via API). Analytics on each printer are aggregated and shared – helping our partners improve machine performance through data-driven predictive maintenance and optimization tools.

Assembrix partners with organizations, regulatory agencies and 3D printer manufacturers worldwide to promote the adoption of distributed manufacturing through unified strategy and methodologies based on local and global needs.

Stay connected and benefit from the power of data previously inaccessible. Join our global network of distributed additive manufacturing partners.

© 2021 All rights reserved

Copyright - EVAP Investment